Energy efficiency and environmental sustainability

play a key role in the investment choices of every company.

Yesterday as today, SMI has been the reference point for many food and beverage manufacturers that want to invest in efficient, sustainable and increasingly compact bottling and packaging solutions.

At Drinktec trade fair, that will be held in Munich (Germany) from 12-16 September 2022, SMI will present the new EBS KL ERGON compact stretch-blow moulder for production requirements up to 2,500 bottles/hour per cavity.

Inspired by Industry 4.0 and Internet of Things (IoT) principles, the new EBS KL ERGON series, available in stand-alone, as well as in ECOBLOC® version (integrated with a rotary electronic filler and a rotary capper), is the ideal solution for the production of PET and rPET containers up to 25,000 bottles/hour.

WATCH THE VIDEO

https://www.youtube.com/watch?v=YVagtNO8HNU

The advantages of EBS KL ERGON range at a glance

- compact and ergonomic design

- fully electronic processes and operations

- easy and fast format changeover

- significant energy saving, also thanks to AirMaster compressed air recovery system, supplied as standard equipment

- low transport cost (a container is enough)

- installation and start up in a few days

- high stretch-blow moulding quality

- easy management of the plant, thanks to the touch screen control panel and the intuitive graphics

- predictive maintenance.

Advanced technology in a small space

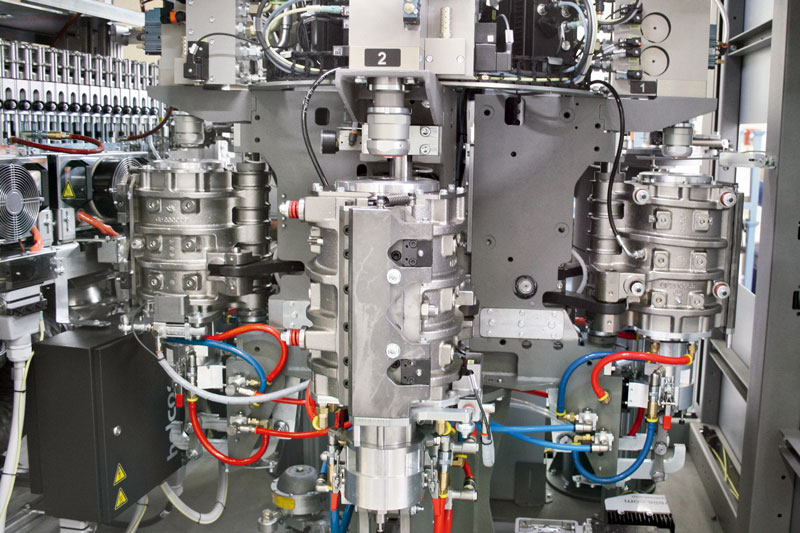

The new EBS KL blow moulder stands out for its ultra-compactness, made possible by the fact that the preform heating section and the stretch-blow moulding section are integrated in a single module.

Advantages of the new SMI solution:

– space-saving design suitable even for small-sized bottling lines

– saving on transport cost, as a container is enough

– saving on installation and set-up costs, as such operations can be easily and quickly performed in a few working days.

Environmental sustainable production processes

The stretch-blow moulding carousel of the new EBS KL blow moulders is equipped with motorized stretch rods, whose functioning, controlled by electronic drives, do not require pneumatic cams.

Advantages of the new SMI solution:

– precise management of the stretch rod path and accurate control of its position

– considerable energy saving; compressed air is not required and the power consumption is low.

Maximum efficiency and precision

Cam-free technology that allows to modify the stretch speed without mechanical interventions (cam replacement), as the servo-motor automatically adjusts according to the production speed.

Advantages of the new SMI solution:

–reduction of the machine vibrations

–fewer adjustments to be performed in case of format changeover

-plant managed by automation and control MotorNet System®, that further simplifies the format changeover operations.

Energy saving and reduced maintenance

The stretch-blow moulding system of the new EBS KL blow moulders are equipped with high-performance valves with low dead volumes (-50% compared to the previous models).

Advantages of the new SMI solution:

-reduction of pre-blowing and blowing times, which ensures a higher performance of the machine and a better quality of the bottles produced

-the mould mechanical unit is equipped with its own motorization, that performs the up/down-motion of the mould bottom, as well as the opening and closing operations of the mould-holder unit with the utmost precision.This results in a greater accuracy in the processes and less maintenance of the plant.

Fast and precise movements

New motion system of the grippers, based on preform/bottle grippers without springs, equipped with desmodromic cams.

Advantages of the new SMI solution:

-technical innovation that optimizes the spaces and reduces the diameter in which the grippers move, which leads to a lower wear and a higher control precision of the blow moulder

-use of plastic bearings that reduce the wear and the vibrations to which the grippers are subject and that do not require lubrication.

For further information on the new EBS KL ERGON blowers, contact our sales department or visit our web site.

SMI S.p.A.

E-mail: info@smigroup.it – www.smigroup.it